Kabal AI: The Brain Revolutionizing Energy Logistics

In oil and gas logistics cost, timing, and safety are tightly linked. Therefore AI success demands more than just algorithms. It needs context, experience, and trust. That’s where Kabal fits in.

At the moment, it feels like AI is changing every industry. But in energy logistics, where cost, timing, and safety are tightly linked – AI success demands more than just algorithms. It needs context, experience, and trust.

That’s where Kabal fits in.

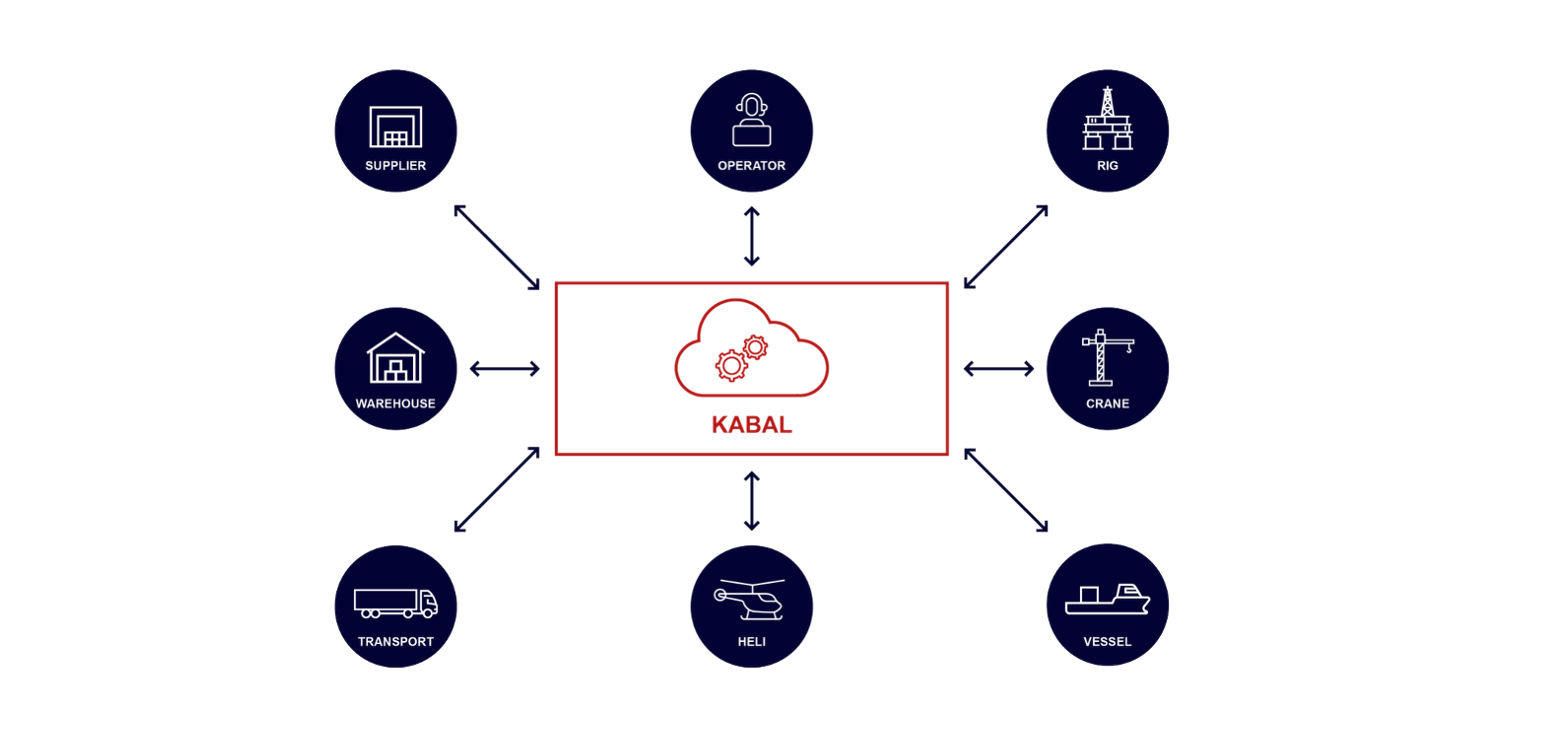

Over the past 14 years, Kabal l has become the digital backbone for logistics management across the energy sector. We help operators, suppliers, and transport providers plan and execute the daily movement of cargo and personnel, for demanding onshore and offshore operations.

Now, we are upgrading our solutions with AI. The goal is clear: to make the logistics workday easier and to make complex energy logistics safer, more efficient, and more predictable.

I sat down with Fredrik Larsen, Kabal’s Chief Innovation Officer, to discuss how his team is utilizing AI to boost operational performance for Kabal customers.

Q: AI is transforming industries everywhere. How is Kabal using it to make oil and gas logistics more efficient?

Fredrik: Well, one example is that before Kabal, it was normal for rigs to have dedicated boats. We have centralized and streamlined logistics planning, and our solution now facilitates an efficient ‘milk run’ model with flexible sailing patterns. This allows our customers to fill vessels better and ship goods on time, resulting in massive savings in transport costs.

Now, we are working to leverage the impact of AI further.

Oil and gas logistics is a huge puzzle involving a vast number of parameters: among them, weather, rig and vessel deck capacity, transport capacity, schedules, and critical safety rules. When you add that most operators have numerous operations and rigs to handle, the problem quickly becomes too large to handle for even the most experienced human planner.

AI allows us to process this complex data and move toward a highly analytical approach to optimize resource & materials management, equipment transport, and personnel transport.We’ve proven the AI algorithms themselves are effective; the current challenge and focus is ensuring we have, or at least can estimate, the sufficient data needed to fuel the AI, and then maximize its impact across the entire value chain.

Q: Which approach is Kabal taking to adopt AI?

Fredrik: We don’t believe in tech for tech’s sake. It’s easy to get swept up in hype, but we always start with the real-world problem. We ask: Will this really, truly make life easier and better for planners, logistics teams, and operators? If the answer is no, we wait and refine.

Our approach is to test carefully, learn from real use cases, and build trust. That’s how we ensure AI features like route optimization or predictive planning actually helps people work faster and with more confidence. When it works, it sticks and becomes an indispensable part of the process.

Apart from that, we also believe that AI does not always have to be complex and clever. One of the quickest wins we see is the simple ability to make the workday for everyone in the industry a little easier. For example by taking the burden off repetitive and simple tasks; like aggregating information into custom-made reports with context. Such tasks might take up a long time today and is also probably one of the most boring parts of any job.

Q: How does Kabal help operators integrate AI solutions like route optimization across daily operations efficiently?

Fredrik: The key is to make AI feel like an enhancement to the existing workflow, not an extra tool or burden. Kabal connects seamlessly with the systems operators already rely on: ERP platforms, fleet tracking, weather feeds, etc, and uses that information to automatically generate optimized route and schedule suggestions. Planners can review, adjust, and approve everything within the same familiar interface.

The AI quietly does the heavy lifting in the background, evaluating thousands of options instantly, while people stay in control of the final decision. It’s like assisted driving: the system supports you with critical information and optimization, but the human decides and owns the strategy.

There’s no big disruption, just smarter, faster planning and demonstrably better use of every resource: onshore and offshore alike.

Q: How can AI help reduce emissions and costs?

Fredrik: That’s one of the most immediate and critical impacts. Every unnecessary trip, a truck, a vessel, or a helicopter, adds cost, avoidable emissions, and risk. AI helps reduce that by predicting demand more accurately, consolidating shipments, and coordinating resources across multiple projects simultaneously.

It means fewer half-empty journeys and less costly idle time. The result is a clear, measurable reduction in fuel use, lower CO2 emissions, and significantly lower operating costs. It’s the sweet spot where efficiency and sustainability meet; doing more with less impact.

Q: Looking ahead, what excites you most about the future of AI in logistics?

Fredrik: Honestly, it’s the simplicity it will bring to highly complex operations. AI will make these vast logistical challenges feel intuitive. Imagine starting your day and the system already says, “Here’s what changed overnight, here’s what needs immediate attention, and here are the top three optimized courses of action we recommend.” That’s where we’re heading.

It’s not about replacing people: it’s about giving our customers better tools so their experts can focus on strategy, problem-solving, and critical decisions, not repetitive administrative tasks.

And as AI continues to evolve, it’ll help connect and leverage learnings across projects and regions. What one team discovers in a North Sea operation can instantly benefit another team elsewhere. That’s when AI becomes truly transformative: when global experience and data flow seamlessly across the energy network to create a single, ever-improving logistics gold standard.

The Takeaway

For Kabal, AI isn’t just a headline: it’s a tool for operational precision and measurable progress.

In an industry where every movement matters, Kabal’s philosophy stands out for its balance: use AI to enhance human expertise, not replace it.

The result is a logistics ecosystem that’s not only faster and leaner, but smarter, safer, and inherently more sustainable.

Kabal customers have front-row access to new AI tools, global best practices, continuous improvements, and the logistics gold standard upgrading drilling and production operations both today and in the future.